The Design Journey of Genesis One

Every headphone has a story. For Genesis One, that story began long before the first prototype, back in graduate school, where I (Tony) spent years researching piezoelectric transducers. That research eventually became the foundation of Flora Innovations, which we founded in 2023 to develop and commercialize advanced piezo transducer technology.

At Flora, our mission was to push the boundaries of what piezo materials could do. We successfully developed the world’s first full-range piezo transducer. We hold two issued U.S. and international patents on this design. While Flora focused on industrial and B2B applications, the idea of bringing this technology to the audiophile world never left us. We knew the incredible speed and clarity of piezoelectric material could reveal detail and nuance in music like nothing else.

So, in early 2025, we started Lily Audio, a small, passionate team on a mission to build something truly new for audiophiles. Our goal wasn’t just to make another good headphone; we wanted to create something that could redefine how music feels. That’s how Genesis One was born. At its heart is the CrystalCore™ transducer, a refined version of our full-range piezo design, specially engineered for audiophile headphone applications.

From Curiosity to Craft

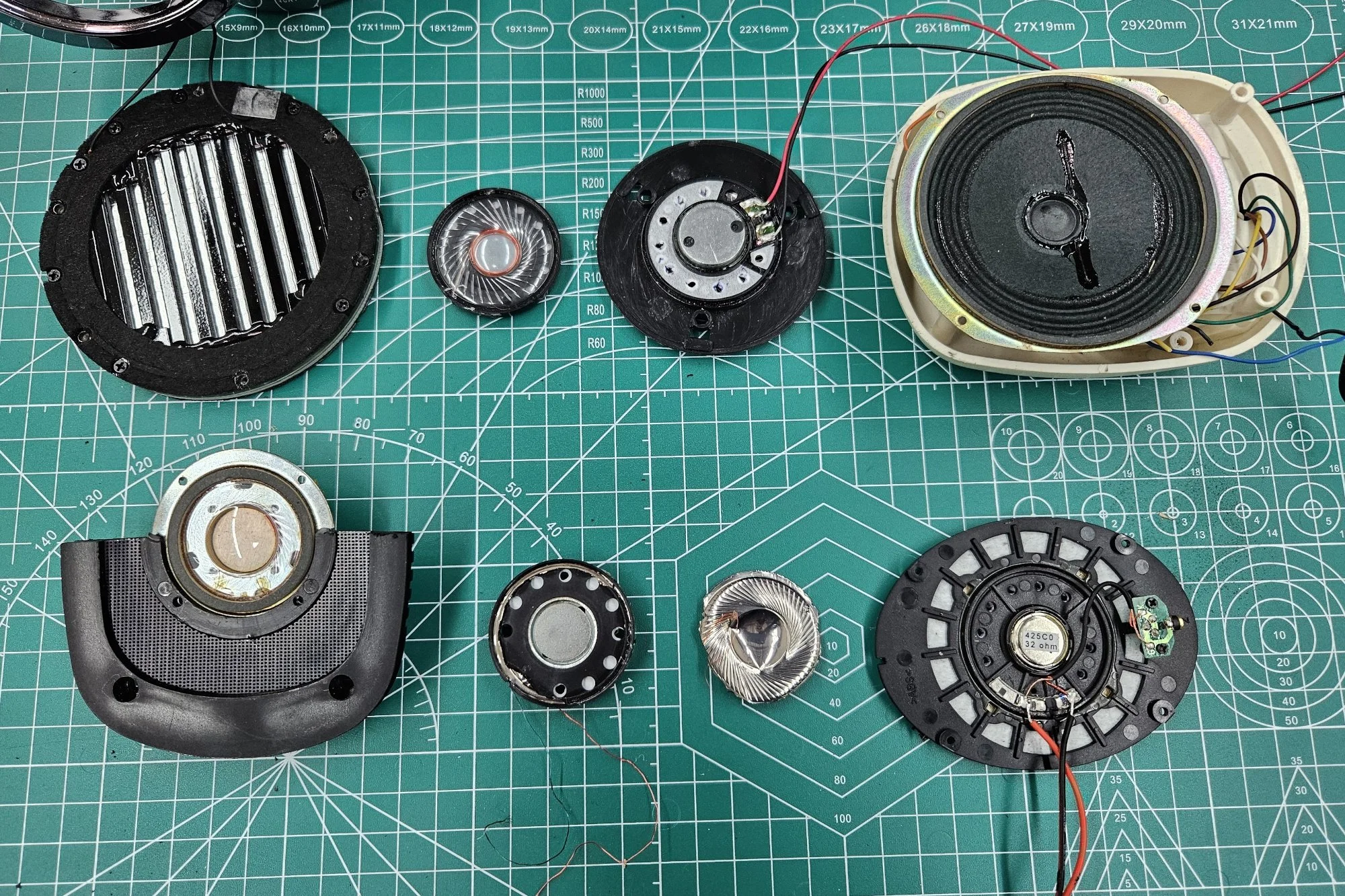

Headphone driver teardown

When we began, we had zero experience designing headphones. We knew speakers from our work at Flora, but headphones? Total beginners. So we dove in: reading everything we could find, ordering random reference models from Sennheiser, AKG, and Hifiman, listening, tearing them down, studying their acoustics, designs, and tuning philosophies.

Learning how to build headphones

An early proof of concept

Once we understood the basics, we began experimenting without a fixed direction, just curiosity. We built dozens of strange prototypes: carbon fiber and wood veneer headbands, redwood burl earcups, and even pink insulation foam diaphragms from Home Depot. Some of these experiments looked beautiful, some sounded terrible, but each one taught us something new.

Our first complete prototype was crude but functional: a foam diaphragm bonded to our piezo (crystal) driver, mounted in a 3D-printed housing with an off-the-shelf earpad. It looked like a science project, but it played music, and it sounded alive. Detail, treble, and clarity were stunning. Bass, not so much. But it was enough to prove that our piezo technology could work in a headphone.

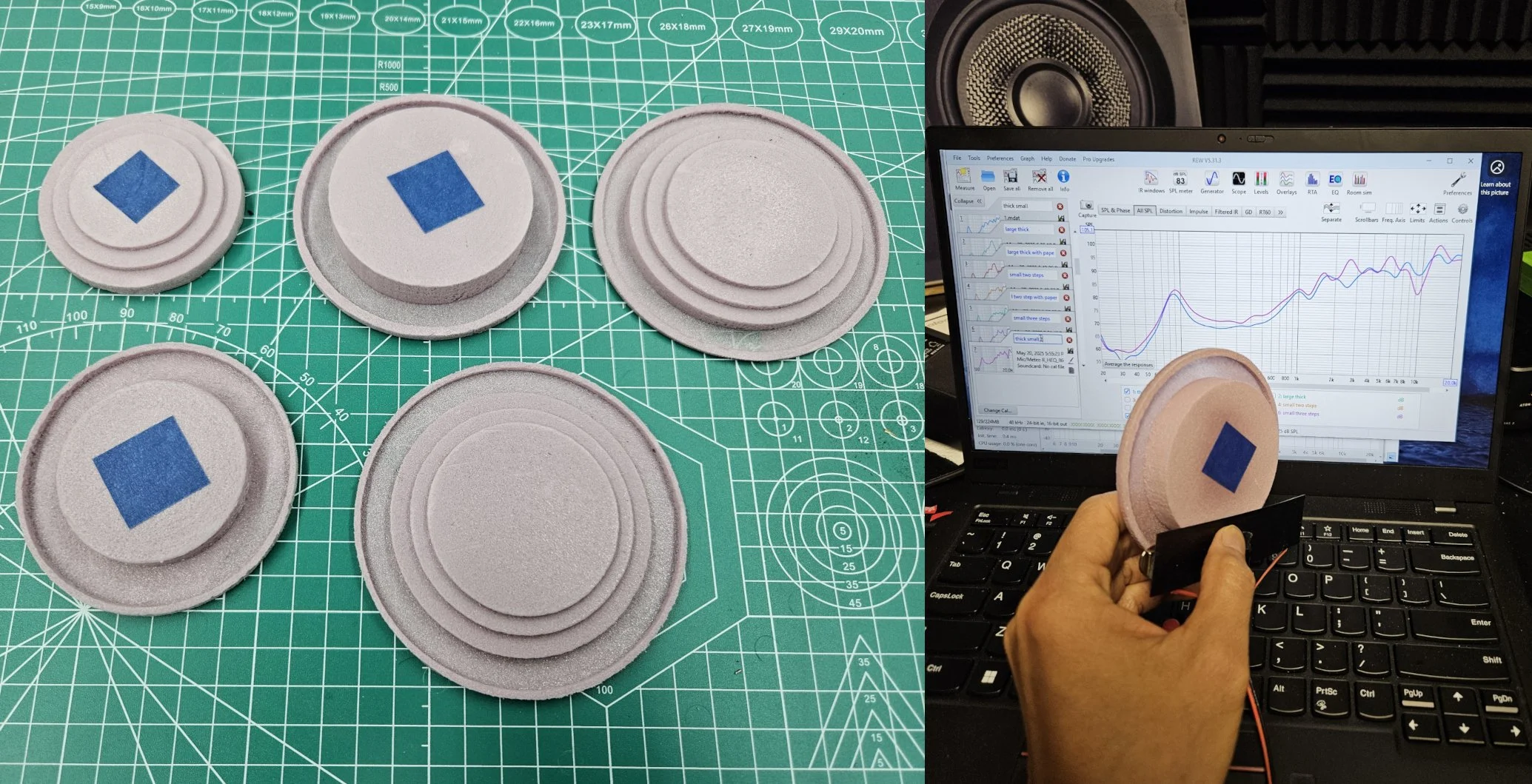

Diaphragm optimization

Learning Through Prototypes

From there, we tested different diaphragm designs, and measured frequency responses using a B&K UA2212 microphones and ear simulator setup. As for tuning, we used the Harman target curve as a baseline, while also studying other targets to find the ideal balance. For sound reference, besides other headphones, we also use a speaker system with Focal and Klipsch speakers.

Our FR test setup (left) and Loudspeaker system for reference (right)

Final prototype of the foam diaphragm concept and its FR

We continued refining the foam diaphragm concept until we had what felt like a final working prototype. The measurements weren’t pretty. Frequency responses were chaotic, full of resonances, peaks, and dips. Yet on listening, it wasn’t nearly as bad as the graphs suggested. In fact, this is one of the headphones we brought to CanJam SoCal, last September, where several listeners described it as “crystal clear” and “electrostatic-like.” Still, we knew its limitations. The soundstage felt boxed in, a bit unnatural, symptoms of a closed front volume that restricted openness and air.

What we really wanted was for Genesis One to sound more like a loudspeaker: open, natural, and spacious with deep, immersive bass that you can feel as much as hear.

A New Direction

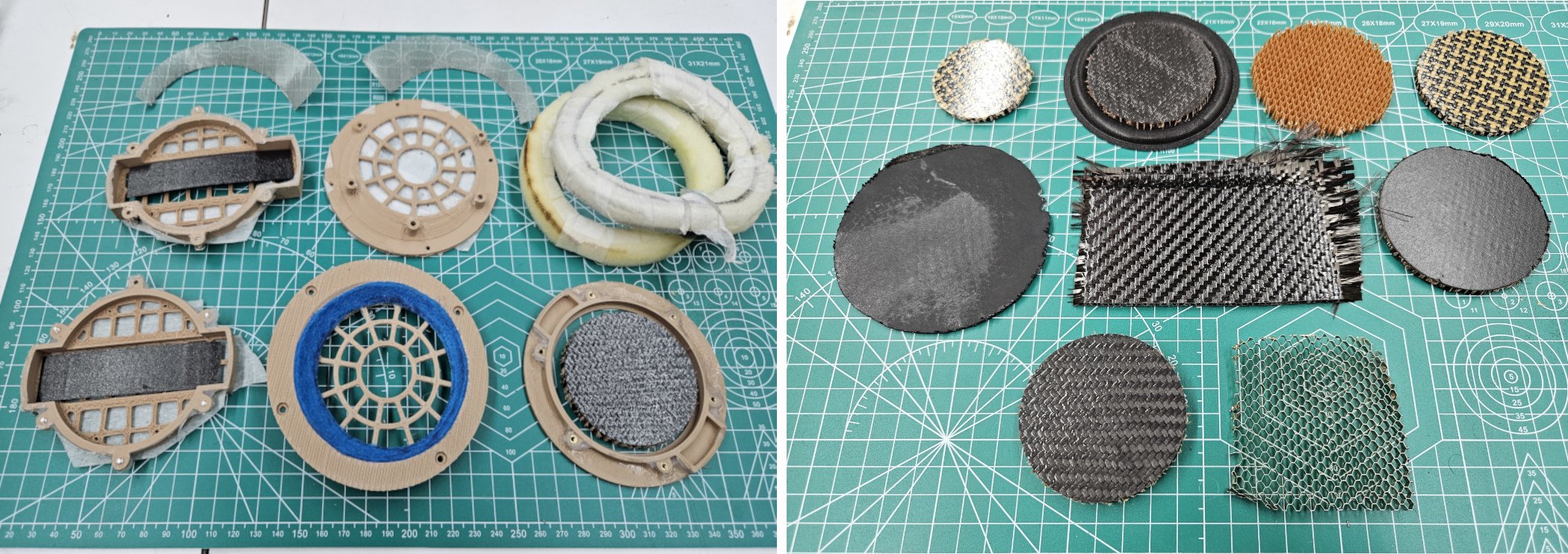

An early prototype of Genesis One (left). Experimenting with different diaphragm composite materials (right)

To achieve the openness we wanted, we needed to control both front and rear acoustic volumes. That led us toward a more dynamic-style structure, inspired by legendary open backs like the Sennheiser HD800, Yamaha YH-5000SE, and Focal Clear. We designed a cone-shaped, perforated baffle and eliminated the traditional earcup altogether, meaning the back of the driver is also the back of the headphone.

With the new architecture, we experimented with diaphragm materials: carbon fiber, Kevlar, aramid, and aluminum honeycomb composites. After extensive testing, we landed on a 75 mm diaphragm, large enough for natural bass and low distortion, yet compact enough for comfort. We also introduced an angled driver alignment to better match the geometry of the human ear, enhancing imaging and spatial realism a bit.

For tuning, we tried everything from acoustic fabrics (from SAATI), open-cell foam to precision stainless steel meshes. The mesh gave the most consistent damping and became part of the final design. By August, we had a refined prototype: CNC-machined headband and trim, nylon MJF housing, leather headband strap, and hand-sewn velour earpads (we couldn’t find anything off-the-shelf that met our acoustic needs).

EV1 (left) and EV2 (right) versions of Genesis One

CanJam Debut

Genesis One debut at CanJam SoCal 2025

In September, we showcased Genesis One at CanJam SoCal. It was our first real test with the public. We ran into some hiccups, our amp was underpowered, and the show floor was incredibly noisy, but even with those challenges, many listeners loved what they heard. We got great feedback on the sound and valuable critiques on fit and comfort. You can find more details about the feedback here.

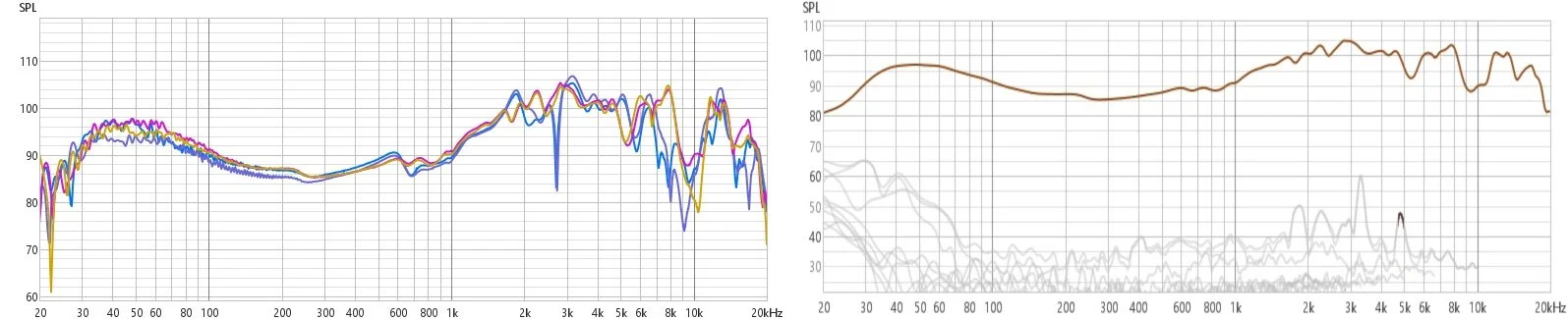

FR and distortion curves of EV2 version

That show prototype (EV2) still had plenty of issues. The frequency response showed noticeable peaks and dips, the channel matching wasn’t great, and distortion levels were higher than we’d like. So after the show, the teardown was intense. We revised the baffle curvature for better ergonomics, adjusted the headband, and increased the earpad thickness to 12 mm for a more natural fit. But our biggest focus was fixing the frequency response and tuning. We spent weeks chasing down every resonance and tuning anomaly; many caused by the unique modal behavior of our CrystalCore™ transducer and diaphragm. By late October, we had finally brought those under control.

The Final Tuning

EV2 (CanJam) vs. EV3 (latest) versions. EV3 weighs only around 300 grams.

Our latest version (EV3), now in the hands of reviewers and measurement experts like Oratory for evaluation, shows a frequency response that follows the Harman target fairly well, with generally low distortion level, similar to the best dynamic driver headphones.

Typical FR (left) and distortion (right) of the latest Genesis One tuning.

The sound signature?

Deep, clean bass and sub-bass (while being very open) that doesn’t bleed into the mids with a tactile sense of immersion at sub-bass frequencies.

Smooth midrange with natural tone and presence.

Extended treble with micro-detail and air (balanced by solid low-end weight).

We’ll leave the final word to listeners and reviewers, but we’re proud of what we’ve achieved. Genesis One feels like something truly new, a headphone that bridges electrostatic clarity with dynamic weight and natural openness.

We’re now making final refinements before moving into production, with first shipments planned for January 2026.

It’s been a long, unpredictable journey full of trial, discovery, and a lot of late nights, but for us, that’s what makes Genesis One special. It’s more than a product to us; it’s the result of innovation, curiosity, and craftsmanship driven by a deep love for sound.